What Is a Pitman Schedule?

Learn about the Pitman schedule—a popular 2-week rotating shift pattern used in 24/7 operations that balances coverage with time off.

In Short

The Pitman schedule is a rotating shift pattern where four teams work 12-hour shifts on a two-week cycle—alternating between day and night shifts with a 2-3-2 work block pattern.

What is a Pitman schedule?

A Pitman schedule uses four teams working 12-hour shifts on a two-week cycle for continuous operations. Each team follows a 2-3-2 pattern: work 2 days, off 2 days, work 3 days in week one, then off 2 days, work 2 days, off 3 days in week two. After completing the two-week cycle, teams switch from day shifts to night shifts or vice versa.

This rotating shift pattern is also known as the 2-3-2 schedule because of its distinctive work-rest sequence. The schedule maintains 24/7 coverage while attempting to balance operational needs with team member wellbeing through regular rest periods and a predictable rotation.

How does the Pitman schedule work?

Here’s a typical two-week rotation for one team:

Week 1: Monday–Tuesday (work), Wednesday–Thursday (off), Friday–Sunday (work) Week 2: Monday–Tuesday (off), Wednesday–Thursday (work), Friday–Sunday (off)

After completing this cycle on day shifts, the team repeats the pattern on night shifts for the next two weeks.

Four teams rotate through this pattern in a staggered arrangement—two teams cover day shifts while the other two cover night shifts. This ensures continuous coverage with at least one team working during every 12-hour period.

Understanding the rotation cycle

The complete Pitman cycle spans four weeks for each team. During weeks 1 and 2, a team works day shifts following the 2-3-2 pattern. During weeks 3 and 4, the same team works night shifts following the identical pattern. This creates a predictable rhythm where team members know their schedule well in advance.

The staggered arrangement means that while Team A works Monday–Tuesday on day shift, Team C might work Monday–Tuesday on night shift. When Team A is off Wednesday–Thursday, Team B takes over the day shift while Team D covers nights. This overlap ensures there’s never a gap in coverage.

What are the benefits of a Pitman schedule?

For team members

The 2-3-2 pattern typically provides every other weekend off, giving workers two full weekends off per month. Three-day breaks offer extended recovery time between work blocks. Rotating every two weeks may allow more time for bodies to adjust compared to weekly rotations, and the predictable cycle can make personal planning easier. This differs significantly from compressed schedules like the 9/80 work schedule which maintains consistent day shifts.

For businesses

Four teams can provide continuous coverage without gaps in operations. Twelve-hour shifts mean only two handoffs daily instead of three, which may reduce communication errors. The repeating pattern can simplify shift planning and tracking.

What are the challenges of a Pitman schedule?

Twelve-hour shifts can be physically and mentally demanding, potentially leading to fatigue by the end of a shift. This is particularly true for roles that require sustained concentration or physical labor throughout the shift.

Alternating between day and night every two weeks may disrupt circadian rhythms and affect sleep quality. The body’s natural clock doesn’t always adjust quickly to these changes, which can impact both health and performance.

The rigid pattern can make shift swaps and personal time accommodations more difficult to arrange. When everyone on a team follows the same schedule, covering a shift can be challenging. Working approximately half of all weekends may affect social activities and family time, as many events and gatherings happen on weekends when others are off.

Which industries use Pitman schedules?

Emergency services like police, fire departments, and EMS often rely on rotating shift patterns for round-the-clock availability. Hospitals use them to staff nursing, emergency, and critical care units. Manufacturing facilities running continuous production may implement Pitman schedules to maintain output. Utilities such as power plants and water treatment facilities use them for constant monitoring, and security teams deploy them for uninterrupted facility coverage.

How do you implement a Pitman schedule?

Assess operational needs

Confirm whether continuous coverage is necessary and whether 12-hour shifts suit your team’s roles and working conditions.

Build balanced teams

Divide your workforce into four teams with similar skill levels and experience distribution. Each team should be capable of handling the full range of responsibilities without relying heavily on specific individuals. Comprehensive on-the-job training helps team members develop the flexibility to work across different positions.

Define shift times

Choose day and night shift hours—such as 6 AM–6 PM and 6 PM–6 AM—and consider including brief overlap time for handoffs.

Communicate the pattern

Show team members the full two-week cycle and explain how they’ll rotate between day and night shifts.

Set policies

Define how overtime is calculated and establish coverage procedures when someone is absent. Clear policies help prevent confusion and ensure fair treatment across all teams. Consider how you’ll handle situations like calling in sick, emergencies, or planned time off requests.

Provide resources

Consider offering information on managing fatigue, sleep hygiene, and the health impacts of shift work. The CDC’s National Institute for Occupational Safety and Health provides evidence-based guidance on managing shift work health impacts.

Monitor and adjust

Track attendance, incident rates, and team member feedback. Be prepared to adjust shift times or rotation frequency based on what you learn. Research from the National Safety Council shows that proper fatigue management reduces workplace incidents.

What helps teams succeed on a Pitman schedule?

For team members

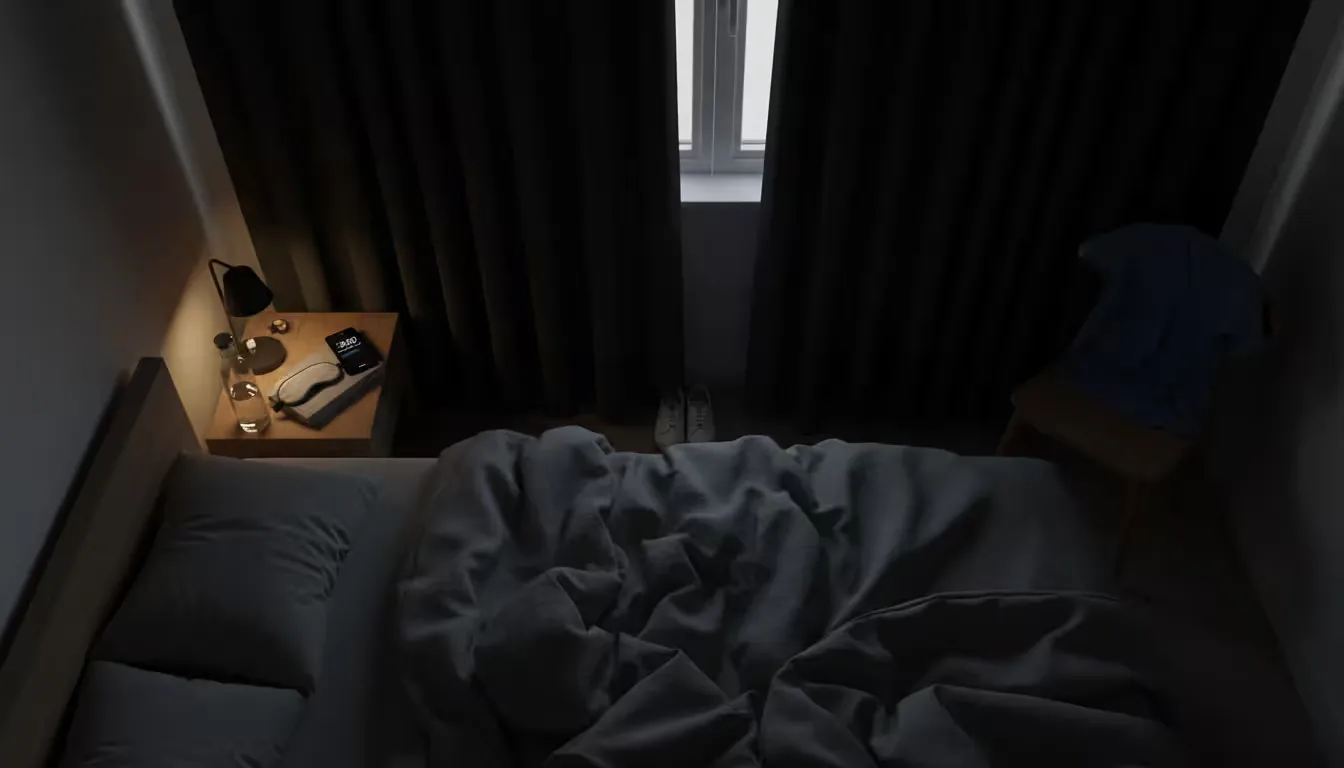

Prioritize sleep by using blackout curtains and maintaining consistent rest schedules, especially during night shift rotations. Use 3-day breaks strategically for appointments, errands, and personal activities. Consider gradually adjusting sleep times in the days before switching between day and night shifts—moving your bedtime earlier or later by an hour each day can help ease the transition.

Staying hydrated, eating balanced meals at regular intervals, and building in physical activity can help maintain energy levels during long shifts. Communicate your schedule with family and friends so they understand when you’re available and when you need uninterrupted rest.

For businesses

Consider offering shift differentials based on hourly rate to compensate for night work, as this can help with retention and morale. Build adequate rest breaks into 12-hour shifts—most teams benefit from at least one meal break and a couple of shorter rest periods throughout the shift.

Foster team cohesion through regular check-ins and team-building activities led by experienced shift supervisors. Strong bonds can make demanding schedules more manageable. Consider providing resources for mental wellbeing, as shift work can be challenging over time. Some businesses offer employee assistance programs, wellness resources, or flexible arrangements when personal circumstances require accommodation.

What are common alternatives to the Pitman schedule?

Other rotating shift patterns include the DuPont schedule (a 4-week cycle with 12-hour shifts that provides more consecutive days off), the 2-2-3 work schedule (similar structure but with different rotation timing), and the 4-on-4-off pattern (four consecutive 12-hour shifts followed by four days off).

Each schedule has different trade-offs. The DuPont schedule provides longer stretches of consecutive days off but requires a more complex rotation. The 4-on-4-off pattern offers extended rest periods but means working four long shifts in a row. The best choice depends on your operational needs, team preferences, and the nature of the work being performed.

Frequently Asked Questions

How many hours per week do you work on a Pitman schedule?

A typical Pitman schedule results in 36–42 hours per week, though this can vary based on how the rotation is structured and whether overtime applies.

Is the Pitman schedule the same as 2-2-3?

The terms are often used interchangeably—both describe a rotating shift pattern with 2 days on, 2 days off, 3 days on in the first week, followed by a reversed pattern in the second week.

Do you get every other weekend off with a Pitman schedule?

Most Pitman schedules provide approximately every other weekend off, though the exact pattern depends on how the four teams are arranged.

What shift length works best for a Pitman schedule?

Pitman schedules typically use 12-hour shifts to provide continuous coverage with minimal handoffs, though the optimal length depends on your industry and team needs.

How do breaks work during 12-hour shifts?

Break requirements vary by state and industry under the Fair Labor Standards Act. Many businesses provide meal breaks and shorter rest periods throughout the shift to help manage fatigue.

Can you swap shifts on a Pitman schedule?

Shift swaps are possible but can be more complex due to the rotating pattern. Clear policies and scheduling tools can help coordinate changes while maintaining coverage.